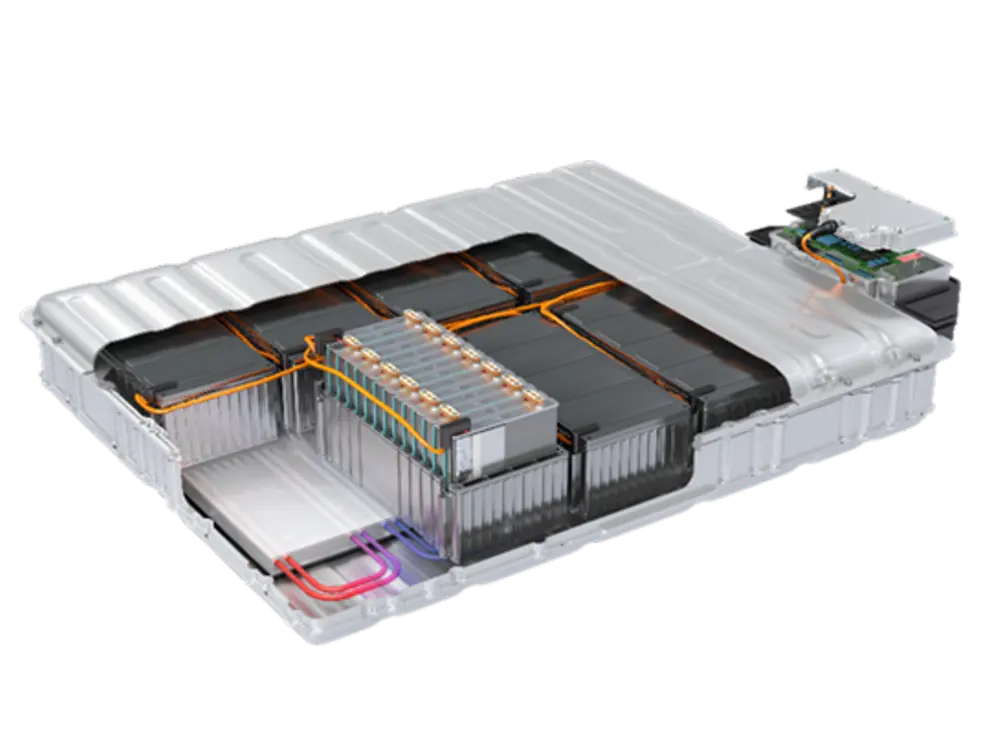

The introduction of a unique thermal gap filler solution has enabled one of the world’s largest automotive manufacturers to develop and manufacture lithium-ion battery packs more sustainably and cost effectively - and at the high volumes required to bring EVs to the mass market. Bergquist Gap Filler TGF 3010 APS not only extends the life of batteries through its high-performance heat dissipation but addresses different sustainability aspects at every stage of the value chain. The development and launch of Bergquist Gap Filler TGF 3010 APS under the Loctite brand are stated by Henkel as significant milestones in its annual sustainability report.

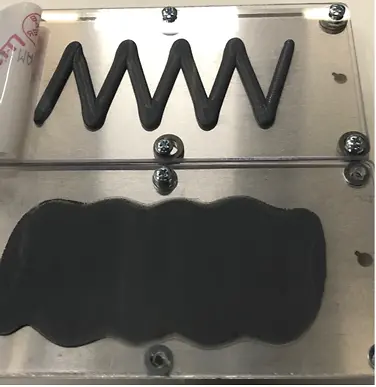

According to IHS Markit, sales of battery electric vehicles (BEV) and other EVs reached nearly 2.5 million in 2020 and is set to rise by about 70% in 20211. This growth represents the culmination of years of investment and research and development. In a key breakthrough, Henkel has collaborated with one of the world’s leading OEMs to develop a thermal gap filler solution, unique in its sustainable packaging format, that delivers critical heat dissipation needed by lithium batteries to ensure their reliability and high performance for the specific use case. Bergquist Gap Filler TGF 3010 APS from Henkel is a two-part, room temperature curable gap filler suitable for use in high-throughput assembly applications. Its 3.0 W/mK thermal performance provides an excellent heat transmission from the battery to the cooling system and is based on a silicone-free technology addressing the challenging requirements in the OEM’s assembly line. Additionally, the low pull-off force of TGF3010 APS support easier repair and recycling of battery packs. Based on its deep process know-how Henkel created the product to provide greater sustainability and efficiency at every stage in production. The Gap Filler is supplied in reusable drums designed to maximise filling volume, thereby reducing CO2 emissions through fewer transports and to minimise halts on the production line. The drums themselves can be reused to minimise waste and to increase efficiency. Launched in 2020, Henkel’s innovation has already been proven, enabling a large-scale customer to set ambitious goals to produce approximately ten million electric vehicles over the next few years.

The manufacturer required an exacting combination of performance, reliability, automation speed, and sustainability, all of which was to be delivered within the strict cost limitations needed for mass market vehicle manufacture. With the amount of gap filler required per battery pack, Henkel would not only have to deliver an outstanding product, but also fulfill incredible volumes of demand. To keep its new EVs affordable, the manufacturer is using a fast-running battery assembly line. This requires that gap filler would need to be dispensed in just 38 seconds per vehicle. At the same time, the gap material has to offer form stability and stay in place when rotated during robotic assembly and be able to be gently compressed to prevent harm to the battery itself. Adding to these complex requirements, the manufacturer specified a silicone-free material to meet high environmental standards. This led Henkel’s formula team to utilise silane modified polymers - an industry first to employ thermal SMP chemistry for the gap filler market.

“Creating a product for the customer for a new type of vehicle in a new manufacturing process was an incredible challenge and a high-stakes opportunity that does not come every day,” said Stephan Höfer, Global Market Strategy Head e-Mobility at Henkel. “As a company that strives to be a leader in sustainability, we are proud to help our customers reach their ambitious environmental and sustainability goals. It is incredibly exciting to work with our partners to make EV battery technology more efficient and cost effective as we transition to a future of electrified mobility.”