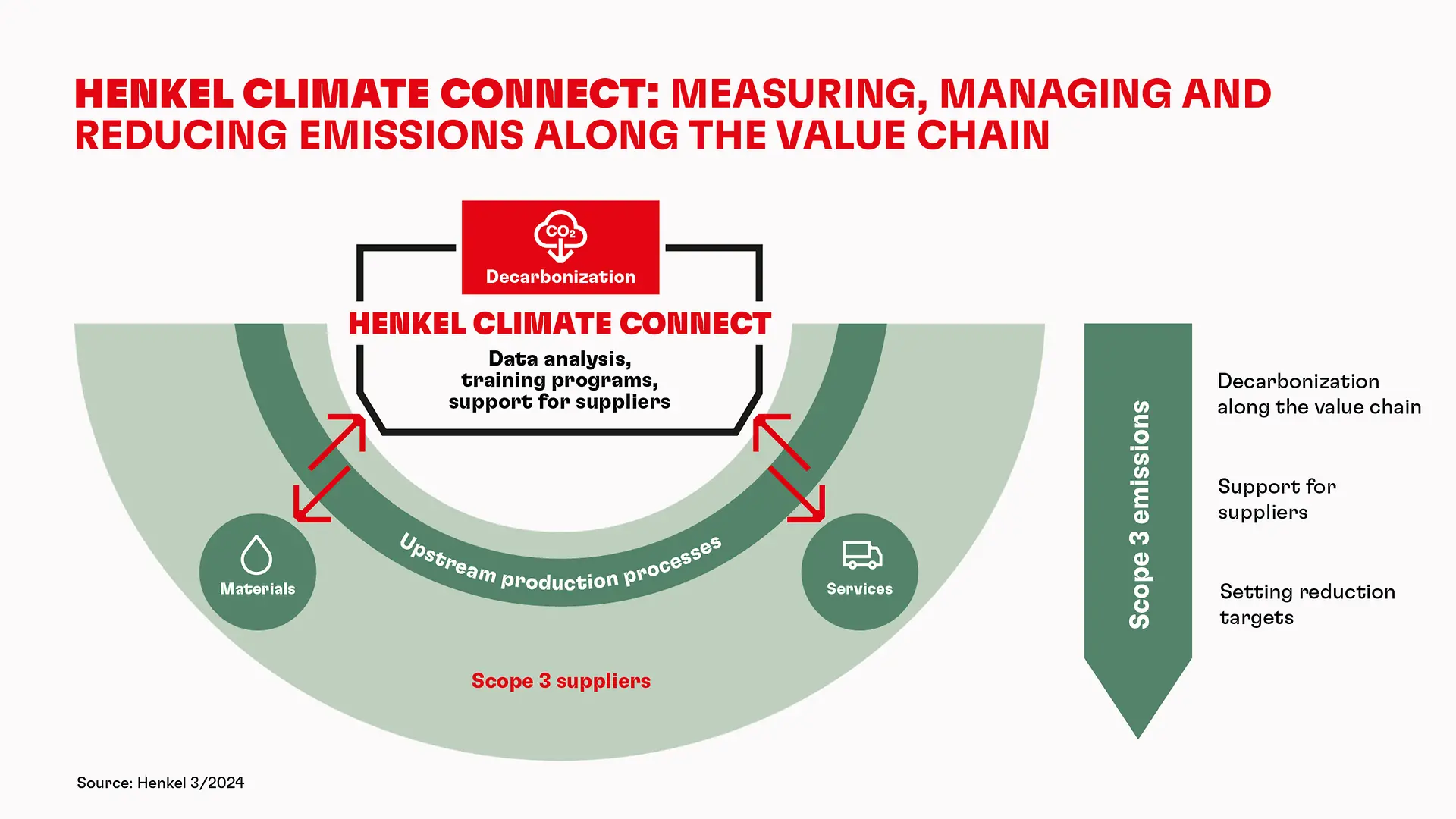

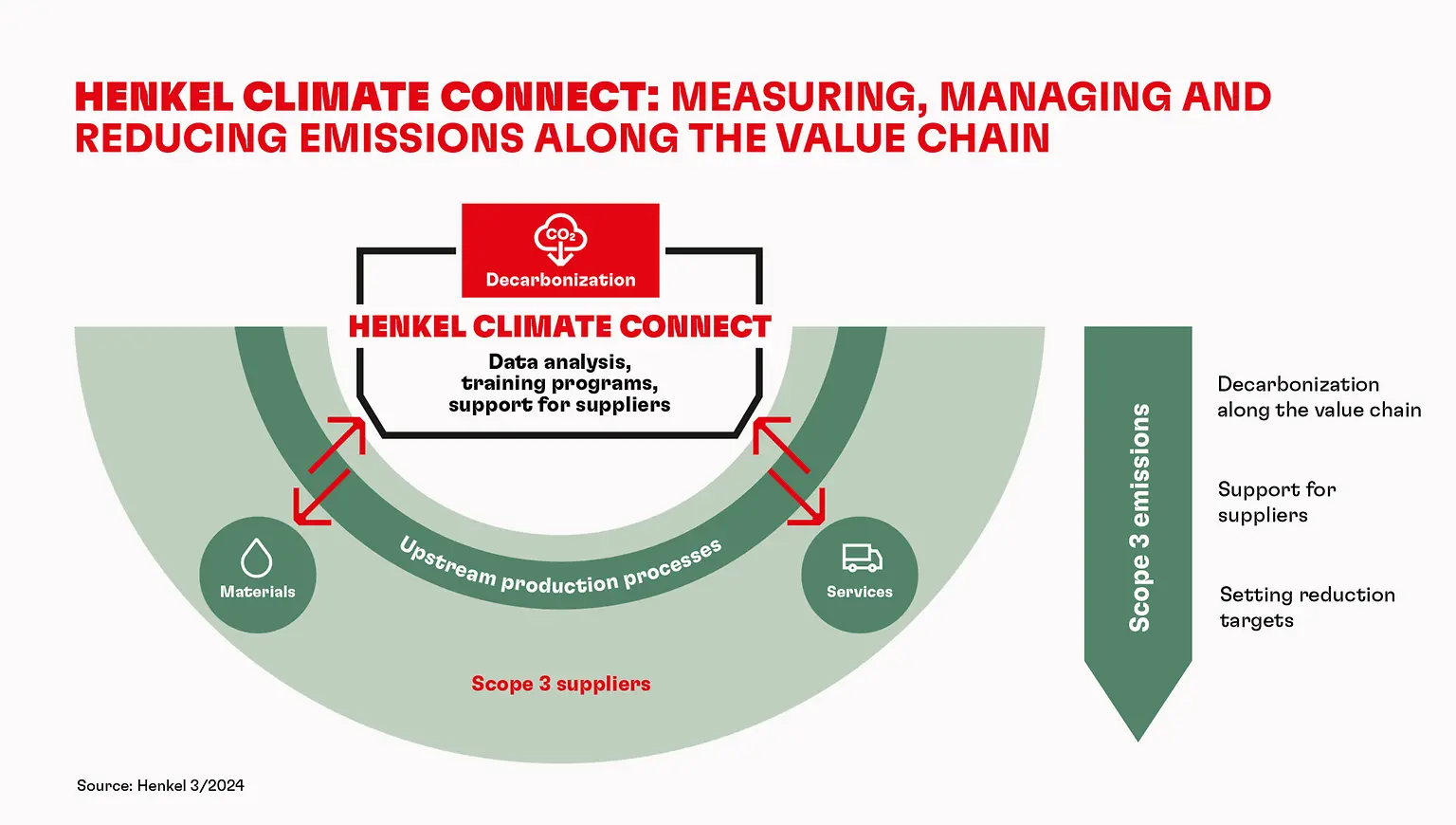

In order to bring the evaluation of its CO2 emissions in the upstream supply chain to the next level, Henkel has launched a comprehensive engagement program for its worldwide suppliers called “Climate Connect”. The program aims to advance decarbonization along the value chain through the collection of emissions data, jointly defined actions for reduction and continuous upskilling.

Henkel will cooperate with “Manufacture 2030”, a partner in the field of carbon reduction, to address its raw material and packaging suppliers as well as contract manufacturers and suppliers of traded goods worldwide, where a total of more than 90 percent of Henkel’s Scope 3 upstream emissions occur. The program, which will record key figures on energy, water consumption and waste volumes, shall be rolled out and adapted gradually to an increasing number of suppliers in the different scope 3 categories in the future. With the help of the data generated as well as corresponding trainings, Henkel and “Manufacture 2030” will offer participating suppliers individual support in assessing their baseline and setting measures for climate actions.

“Compared to large companies, our small- and medium-sized partners often find it difficult to record their CO2 emissions as they lack the capacity to do so. Yet this data is hugely relevant, as it is the only way to define targets and measures to reduce these emissions. For us at Henkel, this in return is the basis for reducing our Scope 3 emissions and achieving our climate protection targets,” said Bertrand Conquéret, Chief Procurement Officer at Henkel. “The 'Climate Connect' program is therefore designed as a long-term partner project with which we want to support our suppliers directly and as individually as possible.”

In addition to trainings, the program offers suppliers to regularly track their progress in environmental key figures and to make data that is generated in “Manufacture 2030” visible for other customers as well. Suppliers can also export relevant data for the Carbon Disclosure Project (CDP), a global disclosure system to manage environmental data, which many companies have joined. The data overview can also serve them to gain access to business partners and green finance opportunities.

Through the “Together for Sustainability (TfS)” initiative, which Henkel co-founded in 2011 together with other partners in the chemical industry, the company is already working closely with other members on the collection of Product Carbon Footprint data from strategic suppliers. With the new “Climate Connect” program, this approach is now to be extended to an even larger supplier base with various maturity levels.

Henkel is pursuing clear goals to reduce its carbon footprint in line with the Paris Climate Agreement. The company has set targets for Scope 1 and Scope 2 emissions, which include reducing emissions by 67 percent by 2030 (base year: 2017). Henkel will also develop a net-zero pathway for its Scope 3 emissions along the value chain, in line with the “Science Based Targets initiative (SBTi)” standard. This implies emissions caused by raw materials and packaging, which currently account for around a quarter of the emissions in Henkel's value chain. By 2030, Henkel aims to reduce its CO2 emissions from raw materials and packaging by 30 percent.